Products

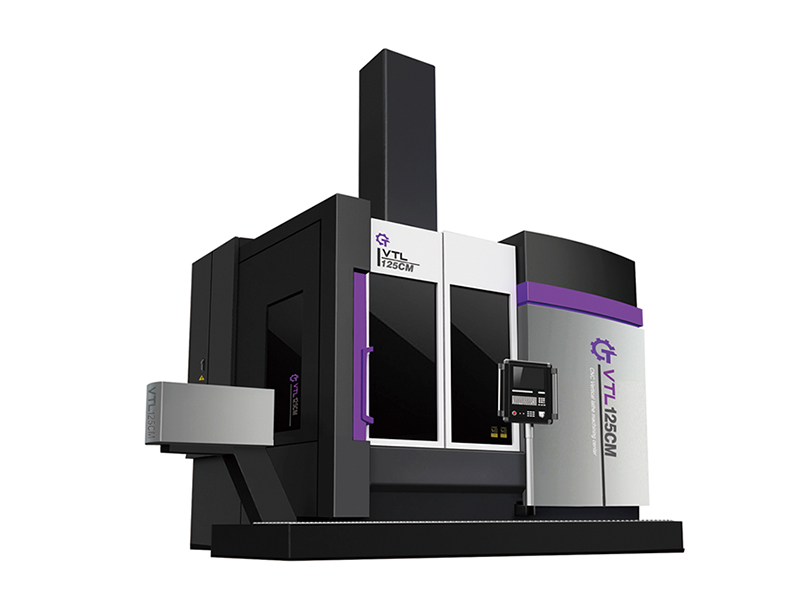

CNC VERTICAL LATHE

Product Details

1.VTL-CM series moving beam vertical tuming milling center is our company according to the market demand,solving key processingtechnology,a new machine tool structure design,technology research,machine debugging work such as designing fix beam doublecolumn vertical milling center,Machine using the host protection.the structure of machine,electricity,liquid concentration layout.It ismainly composed of lathe bed,rest x,Z to move and workbench rotation with C axis,milling shaft B,operation table,automatic chip oval device,temperature control device,automatic lubrication,hydraulic syste protection,electro and electric control parts.

2.The machine numerical control sy ball screw,hydraulic parts and other key parts picked from the domestic and foreign famous brand manufacturers products

3.Introduction of mature technology,reliable selection of imported fittings,and our advanced processing,testing ways,to ensure that themachine has high machining accuracy,high rigidity,high reliability,and a rational layout,convenient operation,high automation degree,etc Can realize automatic to ol change device,automatic processing.improve the processing quality,reduce operating costs.

4.The machine is suitable for power generation,shipbuilding,metallurgy,mining and other industies of large parts processing.

2.The machine numerical control sy ball screw,hydraulic parts and other key parts picked from the domestic and foreign famous brand manufacturers products

3.Introduction of mature technology,reliable selection of imported fittings,and our advanced processing,testing ways,to ensure that themachine has high machining accuracy,high rigidity,high reliability,and a rational layout,convenient operation,high automation degree,etc Can realize automatic to ol change device,automatic processing.improve the processing quality,reduce operating costs.

4.The machine is suitable for power generation,shipbuilding,metallurgy,mining and other industies of large parts processing.

Technical Parameters

(Swipe left to see more)

The company keeps improving its products.lt has the right to change the design.specification dimension and structure of the machines without prior notice.

| Specification | Unit | Model | |||

| VTL160CM | VTL200CM | VTL250CM | |||

| Processing capacity | Work table diameter | mm | 1400 | 1600 | 2000 |

| Max. swing diameter | mm | 1600 | 2000 | 2500 | |

| Max. turning diameter | mm | 1600 | 2000 | 2500 | |

| Max height of workpiece | mm | 1200 | 1200 | 2000 | |

| Max. weiqht of workpiece | kg | 5000 | 8000 | 12000 | |

| Max torque of work table | N.m | 17500 | 25000 | 28000 | |

| Accuracy | Processing accuracy | IT6-IT7 | IT6-IT7 | IT6-IT7 | |

| X/Z position accuracy | mm | 0.018/0.020 | 0.018/0.020 | 0.018/0.020 | |

| X/Z repeat position accuracy | mm | 0.008/0.01 | 0.008/0.01 | 0.01/0.01 | |

| C axis position accuracy | sec | ±3" | ±3" | ±3" | |

| C axis repeat position accuracy | sec | 3" | 3" | 3” | |

| Turning spindle | Spindle speed range | r/min | 1-300 | 1-250 | 1-200 |

| Work table soeed chanae blcxk | stepless with two blocks | stepless with two blocks | stepless with two blocks | ||

| C axis speed | rpm | 0.01-7.0 | 0.01-6.0 | 0.01-5.0 | |

| Main motor output power | 30 mins rated | kW | 30 | 45 | 55 |

| Continuous rated | kW | 26 | 37 | 45 | |

| Tuminq max. cuttinq force | kN | 25 | 25 | 30 | |

| Milling shaft | Max. speed | rpm | 2250 | 2250 | 2250 |

| Motor power | kW | AC11/15 | AC11/15 | AC11/15 | |

| Ram | Ram section size | mm | □ 220X220 | □ 250X250 | □ 250X250 |

| X axis travel | mm | -200 - +950 | -200-+1150 | -200 - +2000 | |

| Z axis travel | mm | 900 | 900 | 1200 | |

| Feeding speed | Cutting feeding speed | mm/rev | 0.01-50 | 0.01-50 | 0.01-50 |

| Rapid feeding speed | mm/min | 8000 | 8000 | 8000 | |

| Beam travel | mm | 800 | 800 | 1000 | |

| Beam lifting gear distance | mm | 4x200 | 4x200 | 4x250 | |

| ATC Tool changer | Tool capacity | 16 | 16 | 16 | |

| Turning tool bar size | mm | 32x32 | 32x32 | 40x40 | |

| Total power | Voltage | V | AC380 | AC380 | AC380 |

| Voltage wave range | -10~ +10 | -10~ +10 | -10~ +10 | ||

| Frequency | Hz | 50 | 50 | 50 | |

| Total power | kW | 68 | 75 | 95 | |

| System | CNC device model | SIEMENS840DsL | SIEMENS840DsL | SIEMENS840DsL | |

| Machine weiqht | kg | 25100 | 28200 | 49000 | |

| Overall dimension of machine(LxWxH) | mm | 7000x4900x5600 | 7500x5300x5800 | 7800x6500x7350 | |